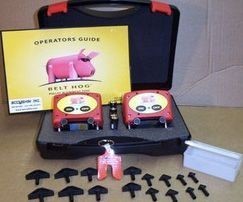

Belt Hog Pulley Alignment Tool

Accushim's Belt Hog makes it simple to align belts and pulleys. You won't have to remove the belts to make quick, accurate adjustments over distances of 6" to 20 feet. One person can accomplish an alignment with no training other than reading the short instruction manual.

Belt Hog mounts in the grooves-right where the power is transferred. Groove mounting makes it simpler to keep everything parallel. Belt guards can often be left on, and pulleys on shafts set in different directions can be aligned just as easily. Bright dual LASER beams let you know when you've got things straight.

Product Features

- Belt Hog Benefits

This little 1.6-pound tool is a heavyweight when it comes to making things simple. You've heard of living high on the hog? Welcome to working high on the Hog.

Benefits of good alignment:- Reduces downtime

- Extends belt and pulley life

- Reduces vibration and belt noise

- Minimizes unscheduled stops

- Accurate, measures from the pulley grooves where the belts operate

- Easy to use, no training required

- Fast, one person operation

- No need to remove the belts

- Measures vertical angle, horizontal angle and offset simultaneously

- Measures distances from 6" to 20 feet

- Measures pulley diameters 3" and larger

Belt Hog Specifications

Housing Material: Precision molded PA Dimensions: 2.68 x 3.62 x 2.65 in (h x w x d) Weight: approximately 1.66 lbs Battery type: (2) AA batteries Operating time: 20 hours continuous operation Measuring distance: 6" to 20 feet Measuring accuracy: Better than 0.5mm or 0.2 degrees Pulley diameter range: 3" and larger Pulley belt groove with: A, B, C, D, and E sizes (0.2" - 1.6") Classification: Class 2 LASER Output power: <1mW LASER wavelength: 630 - 675 nm Belt Hog Alignment Procedure The Belt Hog uses two LASER transmitter for projecting of LASER lines on the opposite LASER unit. By adjusting the pulleys so that the laserline coincides with the reference line on the opposite LASER unit, the pulleys are aligned. Mounting of the Belt Hog units Each unit is mounted on the pulley as shown in the diagram below. Note: The magnets, which holds the unit to the pulley, are very strong. Do not pinch your fingers!

Position both units with the spring action probes resting in the same groove on both pulleys and the units are facing each other as shown below.

When the units are mounted, turn on the LASERS. Each LASER generates a line on the opposite unit. When correctly aligned the lines coincide with the reference marks on the labels on both units. If the belt transmission is mis-aligned, start by correcting the angular error.

It is important that the pulleys are mounted correctly on the shafts and that the shafts are straight before starting the alignment process. Wobbling or warped pulleys affects the alignment quality severely. Safety The Belt Hog uses LASER diodes with a power output of less than 1.0 mW. The LASER classification is Class 2, which is considered safe for its intended use with only minor precautions required. These are:

- Never stare directly into the LASER light source.

- Never direct the LASER into anyone else's eyes.

Your system complies with the requirements in:

Your system complies with the requirements in:

- SS-EN-60825-1-1994

- British Standards BS 4803 Parts 1 to 3

- Deutche Industrie Norm

DIN JEC 76 (CO) 6 - USA FDA Standard 21 CFR, Ch 1,

Part 1040.10 and 1040.11

Packaged Dimensions: 16"L x 10"W x 8"H

SKU Details

| Sku Images | SKU | THICKNESS MILS = thousands of an inch |

|---|---|---|

| LP-1 |